Mechanical Reflow is a processing method to manufacture electroplated wire for electronic interconnects and components. The process effects the electroplating of the wire, followed by subsequent rolling or drawing operations that produce the specified final plating thickness and wire shape. As a result the properties and appearance of the plating deposit are greatly improved. The mechanically reflowed deposit is denser, smoother, made mirror bright without the use of any additives, is more resistant to superficial surface damage, and has a uniform thickness with superior wetting and long term solderability performance.

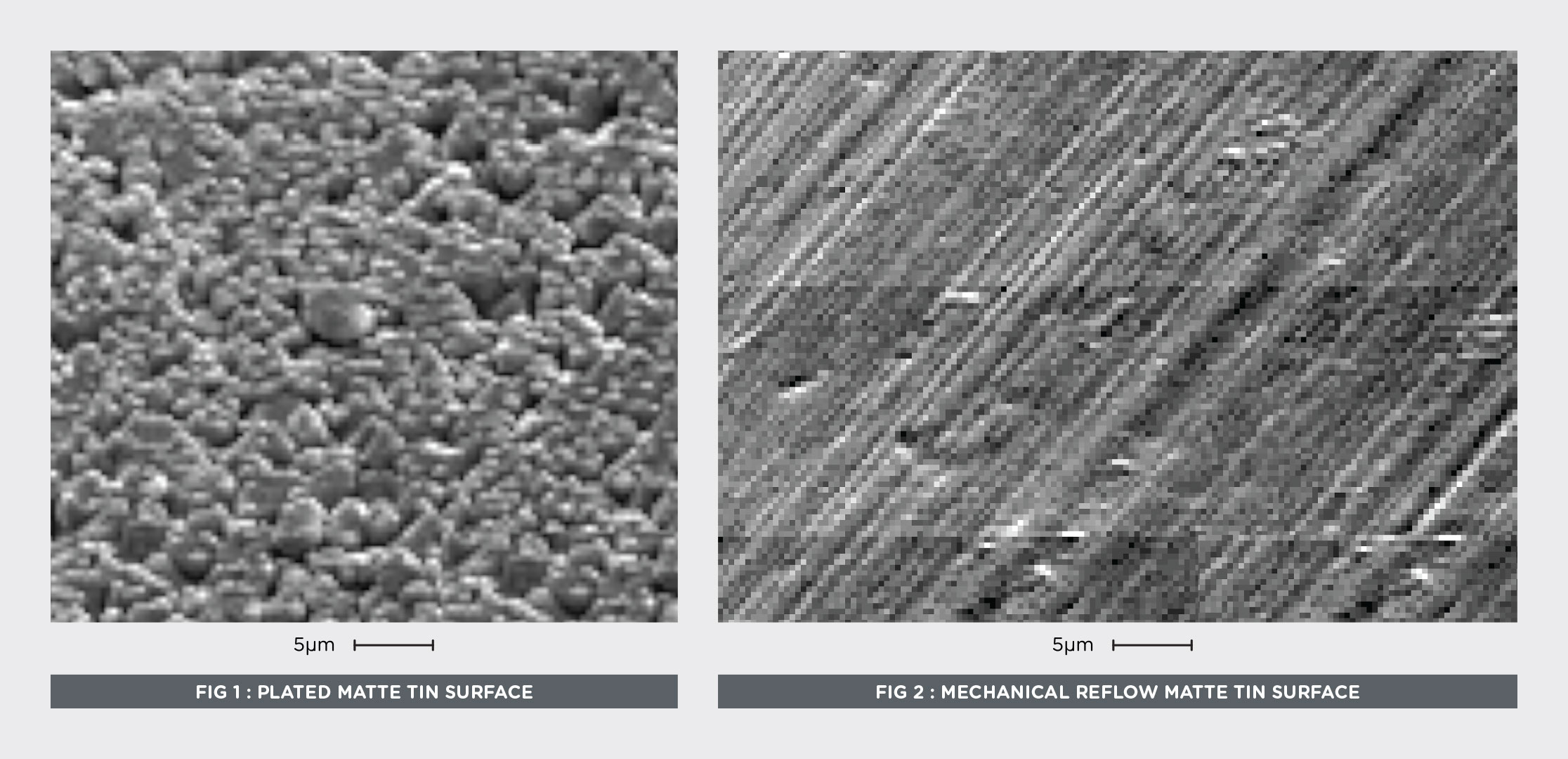

Figure 1, above, is the surface of as-plated matte tin magnified 800X. The irregular surface character of the as plated tin is apparent. In Figure 2, at 800X, the denser and smoother surface of the tin plating gives Mechanical Reflow superior performance.

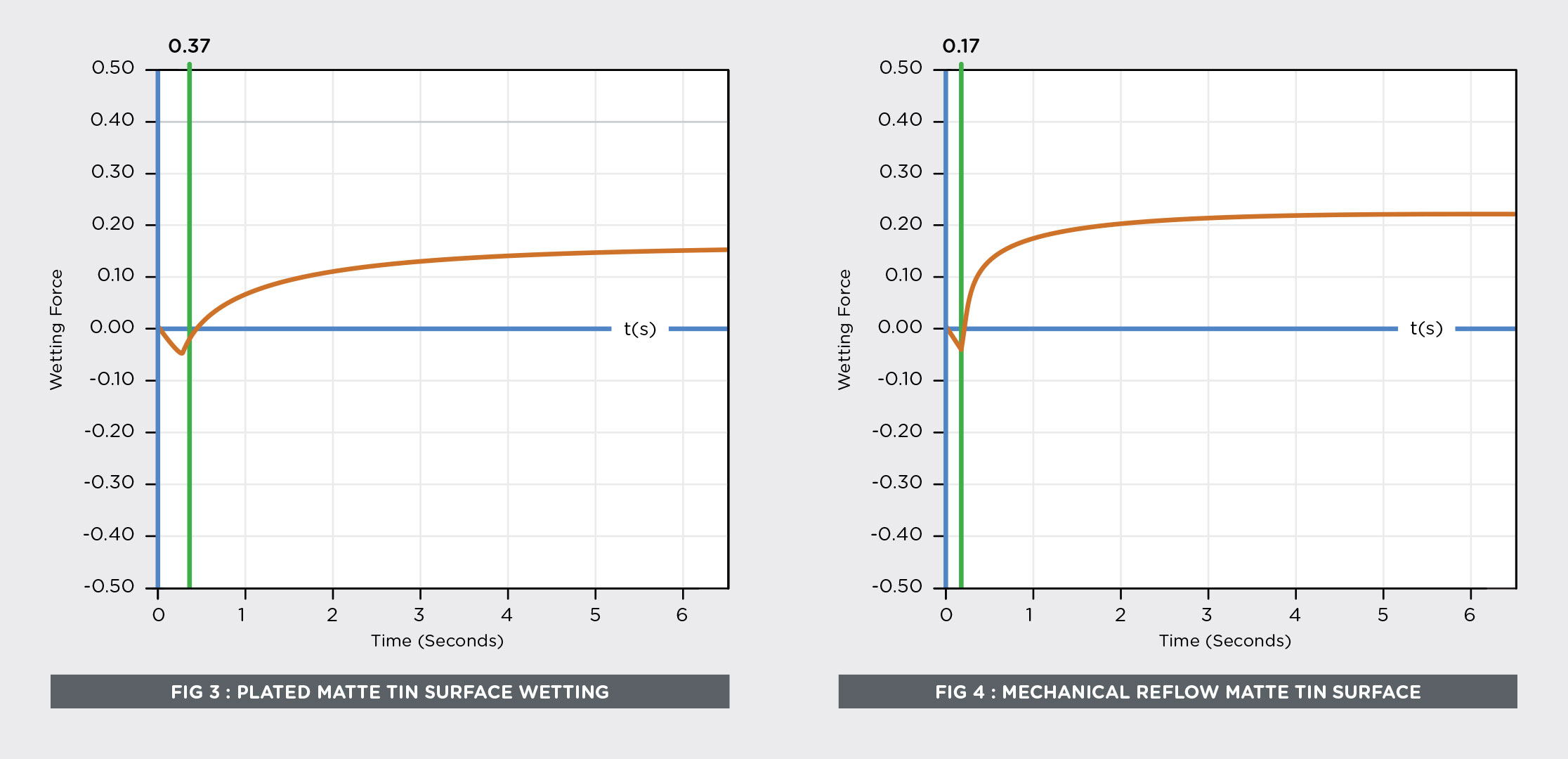

Figure 3 is a Meniscograph, demonstrating that as-plated matte tin requires 0.37 seconds for the solder to wet the surface after 8 hours of steam aging. In Figure 4, Mechanical Reflow matte tin requires only 0.17 seconds to wet after 8 hours of steam aging.