One of the main attributes of copper alloys is their high electrical and thermal conductivity, making these alloys quite attractive in electrical and electronic applications. With a steady move towards miniaturization, alloys with high electrical conductivity at the same strength levels are required.

Electrical Conductivity

Electrical conductivity of copper alloys are generally stated in terms of %IACS (International Annealed Copper Standard,) with electrical conductivity of ETP copper slightly greater than 100% IACS. Knowing the resistivity (in units of µcm), the %IACS for an alloy is calculated by:

%IACS = 172.41/Resistivity

The addition of alloying elements to improve various properties of copper such as strength, reduces electrical conductivity. When added to copper as an alloying addition, each element and combination of various elements influences electrical conductivity in different ways. High Performance alloys have been designed to provide high strength with a lesser reduction in electrical conductivity of elemental copper.

Thermal Conductivity

Since electrons carry both electrical current and thermal energy in metals, alloys with high electrical conductivity also possess high thermal conductivity. For example, thermal conductivity of phosphor bronze C510 with 15% IACS electrical conductivity is .17 cal/sq cm/cm/sec/ºC while thermal conductivity of alloy C197 with 80% IACS electrical conductivity is .77 cal/sq cm/cm/sec/ºC.

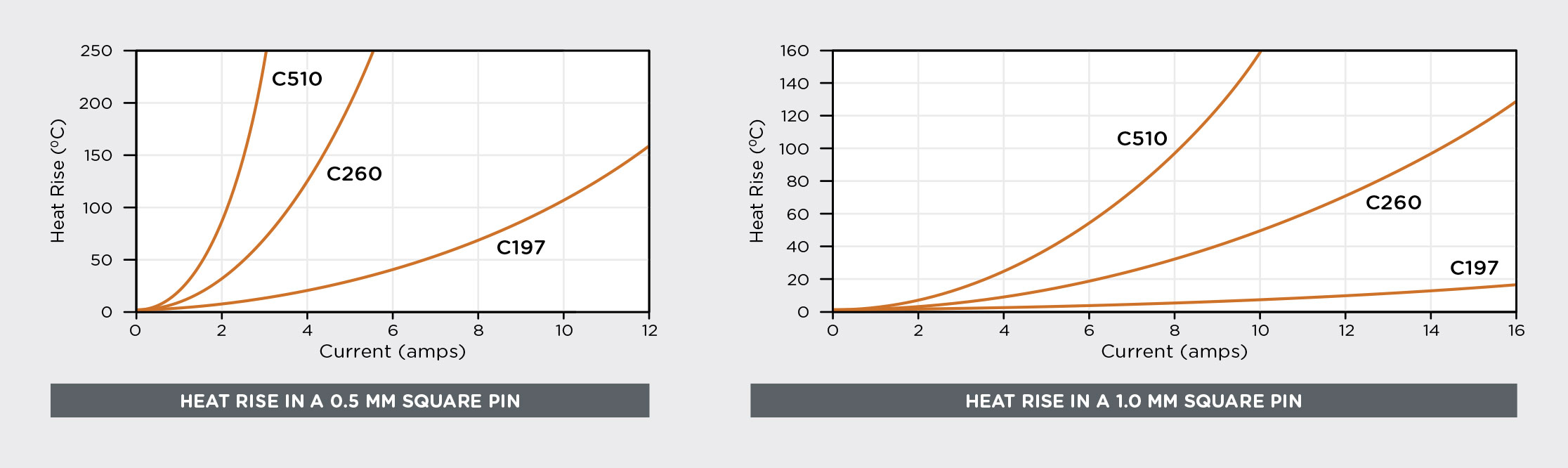

Heat Rise

Since electrons carry both electrical current and thermal energy in metals, alloys with high electrical conductivity also possess high thermal conductivity. For example, thermal conductivity of phosphor bronze C510 with 15% IACS electrical conductivity is .17 cal/sq cm/cm/sec/ºC while thermal conductivity of alloy C197 with 80% IACS electrical conductivity is .77 cal/sq cm/cm/sec/ºC.

ΔT = ρI2L2/2A2Kt

where I is current in amps, ρ is electrical resistivity in ohm-cm and Kt is thermal conductivity in Watts/cm ºC. The effect of current on temperature rise of three typical interconnect alloys are illustrated below for typical 1.0 mm and 0.5 mm square pins.