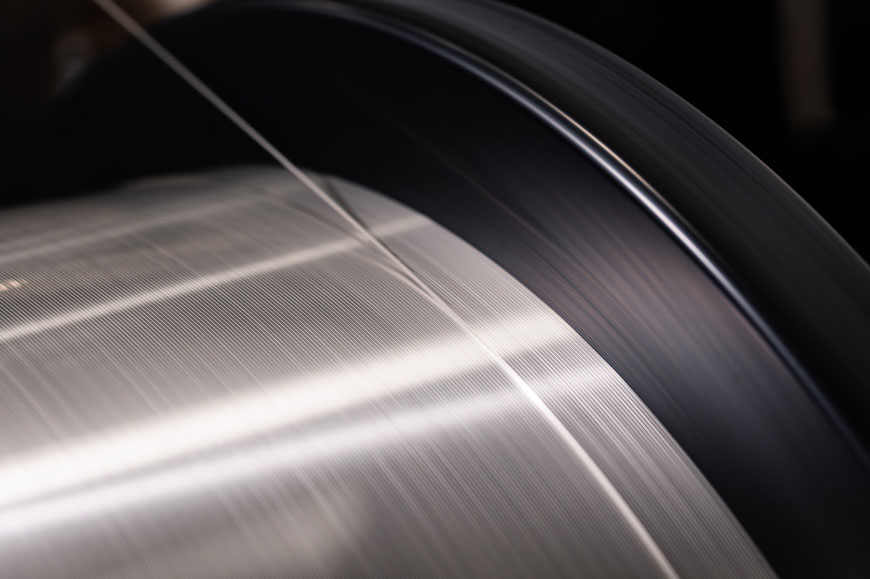

Percon Alloy Conductors

RoHS compliant alloy conductors for wire and cable and high performance shielding.

Fine Wire

Fine and ultra-fine wire for spring and specialty contact systems including beryllium and beryllium free alloys.